The four 'i's of design for product-based infrastructure

John T Roberts • June 18, 2020

Will a product-based future mean there is going to be less design?

Modern Methods of Construction. Building Offsite. DfMA. Call it what you want, but the shift from onsite activies to using more preassembled components has been making some real progress over the last five years. The journey has started.

A few years ago, I described this vision to students at Surrey University and was asked a question that I didn’t answer very well at the time. ‘Will this product-based future mean there is going to be less design?’ It got me thinking, but for some reason I never wrote down my conclusion. Until now!

I think the answer is no; but the design done is going to have to be different.

At the moment clients, consultants and contractors, architects, QSs and engineers are all playing across all stages in the process – specification, design, manufacture and installation. Once a coherent modular future is mapped out these designers are going to have to stop experimenting with new prototypes for every project, repeating low grade, non-optimised tasks. Over the past decade I have come to the conclusion that much of our design effort is unfocused and doesn't deliver the value end users are looking for. Skills are short, and we can't afford that wastage to continue. Just deploy those previously optimised modules!

So, what design activities will they be doing in this future?

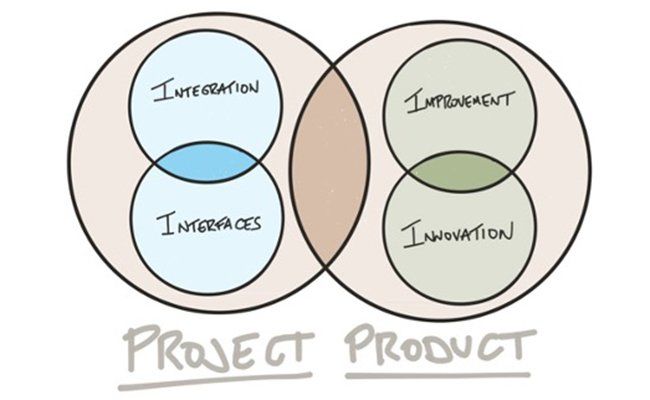

Product based design will focus on four 'i's: Integration, Interfaces, Improvement and Innovation,

and each of these areas may become new distinct specialist areas.

The first two of these define how we deploy the products

available on a project.

Integration:

Which standard products are we going to bring together to fulfil requirements? How do they combine as a whole? What configurable settings are right for this project?

Interfaces:

All sites will have some remaining bespoke or insitu aspect. This needs to become a key design focus, driving up overall quality, rather than being left up to a site team to sort out the gaps and surprises.

The second two 'i's relate to refinement of the products themselves.

Improvement:

Capturing lessons learned and incrementally extending the range and capability of a product. Add a new and better pump type to an assembly. Turn an insitu stitch into a mechanical fixing. And finally....

Innovation:

Make the big jump to create a whole new product. Start with literature and IP searches, carry out fundamental R&D and ensure what is created is fully documented and ready - technologically, commercially, for manufacture and management.

In current modular design those ‘i’s happen, but they are often all mixed up together. They will become more distinct, more focused activities. There is still plenty of design, but activities are now intrinsically linked to the processes and stages of manufacture, assembly and operation.

This new set of activities is going to present challenges to the current breed of design consultancies. These new specialisms don’t really fit into the teams they sell currently. Architects intrinsically think about projects end to end and are going to struggle not to tweak the modules because their project is ‘special’ (all projects are special in the eyes of a conscientious architect). In this MMC future there is a cardinal rule; don’t tweak the manufacturing!

Meanwhile, Improvement and Innovation are natural homes for specialists from other manufacturing sectors; the mechanical, robotic, material and other engineers. Some people with experience of existing infrastructure will be needed to develop the brief – but probably not that many. Interfaces will be a natural home for landscape architects and civil engineers. Those activities will remain recognisable, at least for a while.

Many things need to change to drive down cost, carbon and time and increase safety and reliability, all whilst driving up the quality expected from our infrastructure. Design and designers will be a key to enabling this future.

There will still be lots of design. Perhaps more. It will just be different and more focused.