Lessons from my woodshed: We are all connected

Procurement, design and temporary works all disrupt progress on a very minor project.

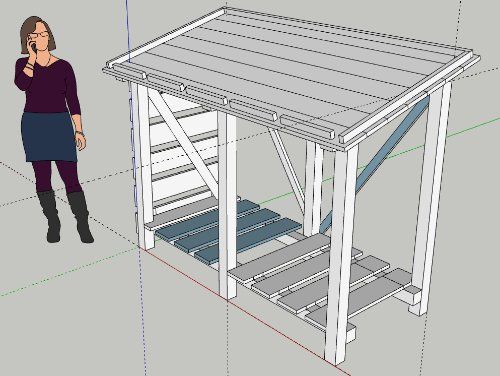

And that was where the problem started. The Procurement Team (me) screwed up and ordered one less plank than was needed from Travis Perkins. When they were delivered the discovery required the Design Team (me) to reset out the cladding and floor - but by doing the minimum redrawing needed it meant I now had a model not quite representing what I wanted to build.

But there was enough to allow the Manufacturing Team (me) to get the factory set up in the garage (there was of course a DfMA strategy) and the complicated end panels were fully assembled and painted, ready for transport to site - about 6 meters away. Everything on site went together fabulously, until it came to the bracing.

The Design Team (me) hadn't confirmed the dimensions needed, so the Site Team (me) improvised to keep things moving along, and of course, got it wrong. Evidently my basic trigonometry skills were a little rusty, but it wasn’t until I walked back after lunch that I could clearly see the ends panels were being held at an odd angle by the bracing.

So I did what I should have done a few earlier. I sent the Design Team (me) back to the computer to do it properly, work out the exact lengths and half an hour later everything was back on track.

It’s a trivial example I know, but you see this scaled up on projects and mega-projects all the time. How many times I have I been in discussions about whether the information received is really 'RIBA Stage 4'? Is rework needed? How often are dimensions or other information missing from drawings that trip up progress on site? How often does the wrong material turn up, or components not quite fit?

The higher complexity and quality needed now, coupled with use of offsite manufacturing, is critically dependent on 'right first time' information earlier and earlier in the project lifecycle. Meanwhile you see consultants backing away from responsibility for the construction details, sheltering behind digital versions of 'do not scale' notes. If the information is not useful and usable for the next person in the chain leading to manufacture, assembly and construction why bother producing it? Getting things right at these information interfaces is vital.

One of Ray O'Rourke's mantras is 'Complete Thinking'. My woodshed went pretty well, but I didn’t quite achieve completeness, and in the end, it held up work on site. Luckily the Construction Workers (me) get paid a pitance. On more major projects fingers would be being pointed at the Procurement and Design Team.

The key questions are nearly always "what information am I receiving?" "Is it right?" What do I need to do to it?" and "in what form must it be passed on?". It would be a big step forward for our industry if we could just be clear about that and do it every time.

The good news is that the Client (me) is very pleased with the project. Two cubic meters of wood stored. Winter is coming. Bring it on.